Our goal is to partner with aftermarket part manufacturers, military upfitters, and OEMs. We are here to work and partner with companies to create a synergy of suspension, innovation, and technology. The capabilities of Xtravel Technology are vast. Our technology increases safety, performance, reliability, while lowering costs to manufacture. We have designed and proven our technology through the harshest race conditions without failure.

The first step in the licensing process is design. A detailed meeting process is undergone so that Xtravel and the prospective customer are on the same page for the goals, needs, and market for the product.

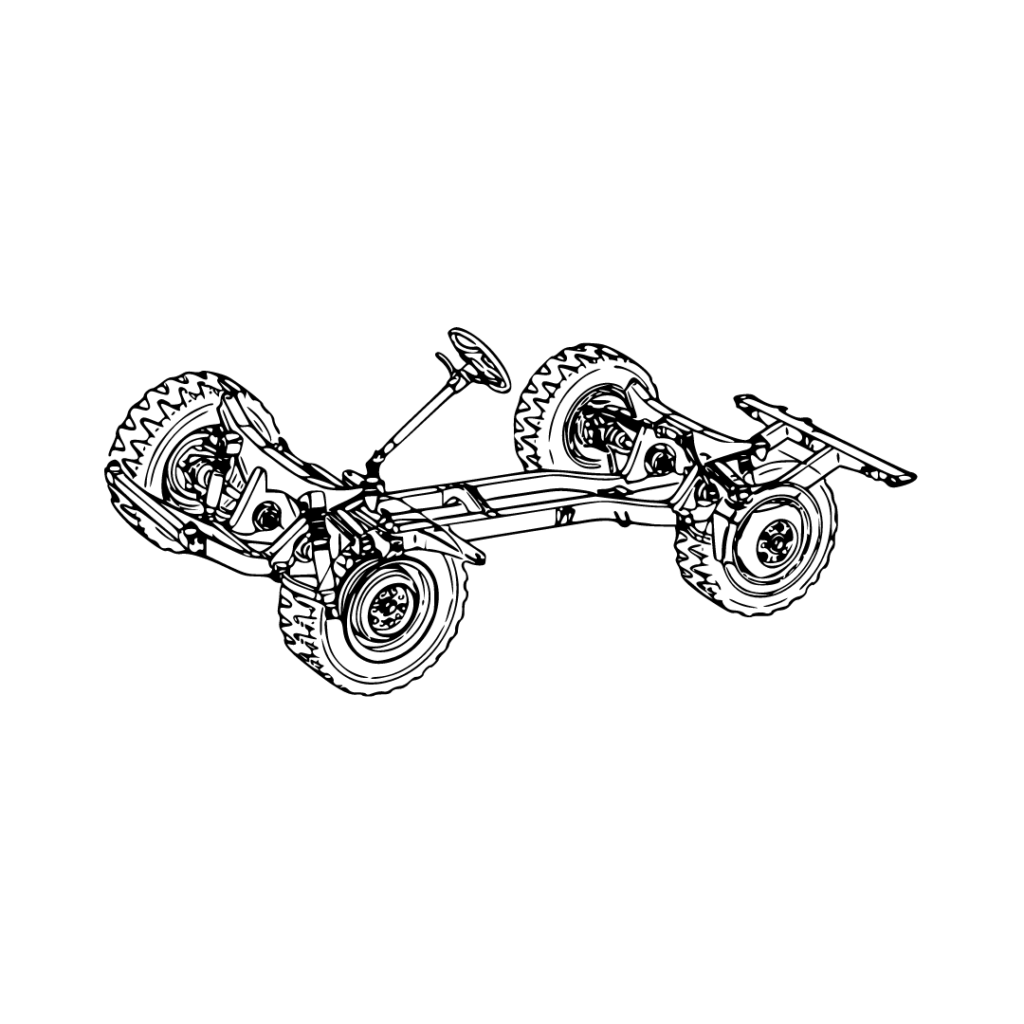

Next, comes the engineering. All Xtravel designs are engineered with computer aided 3D models. All designs are load tested in our computer software. All goals and optimized suspension geometry are put into place to ensure the highest quality suspension is built for the prospective project.

All engineered designs are 3D printed. A physical model is installed on the vehicle and fitment tests are run. The suspension is cycled and steering is tested to understand the geometry in real life functional conditions. If any changes are needed, the team goes back and makes these changes before anything is actually built.

After any changes are made to the 3D printed model, a first article is fabricated. This first article is installed on a test/race vehicle. A minimum of 500 test/race miles are put on parts. Ensuring all goals and needs for the product are beyond expectation for quality and safety.

After 500 miles of testing, all parts are inspected on the vehicle and must pass a 100 point inspection to ensure fitment and precision. The parts are disassembled from vehicle and sent out to a 3rd party consultant to be inspected for any premature stress or cracks invisible to the eye.

A data analysis process is done during the 500 mile test to produce reports that prove that the goals and needs of the product exceed expectations, and are rigorously quantified.

A decision is made by the partnership to use manufacturing by Xtravel, or the designs are passed on to the partner to have them manufactured in-house. Once the manufacturing goals are defined, a high speed process of information transfer allows for an efficient timeline to market.